Due

to the intensive mixing in the rotary coater each particle will

have the same chance to obtain the liquid and powder material

and the enlargement of each individual particle highly depend on

its surface area. Due

to the intensive mixing in the rotary coater each particle will

have the same chance to obtain the liquid and powder material

and the enlargement of each individual particle highly depend on

its surface area.

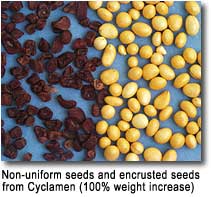

Thus, the size uniformity of the

original seed lot highly affects the final product uniformity.

Depending on the desired level

of product uniformity it may be necessary to calibrate the

original seed

lot and except the loss of an non-coated fraction or coat the

separate size fractions.

Another option would

be to include additional screening & enlargement steps during the

coating process which will demand additional coating equipment.

It will be clear that

either way the coating process becomes more complicated and less

efficient and process time will increase.

|