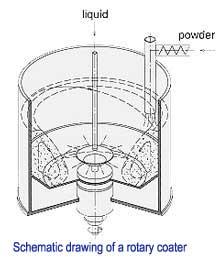

By analyzing

the typical characteristics of the rotary coater it is easy to

understand the high efficiency of the coating process. Basically it

is the same reason what makes this technology so effective for film coating.

While coating particles, the surface has to be covered with a uni-

or multi-layering of coating material from either a liquid

formulation or a combination of liquid and powder formulations. The

speed of covering and enlarging the particles is highly depending on

the surface area of the particles exposed in time and the

homogeneity in which the liquid and powder material is spread onto

the particle surface. These two elements are extremely effective in

the rotary coater.

The rotor rotating at 25-150 rpm creates a fast

horizontal circular movement of the particles which is combined with

a vertical circular movement when the particles hit the static wall.

The thus obtained intense spiral flow of particles creates a rapidly

changing mass and exposed surface which allows coating materials to

be taken up very fast while the agglomeration of particles is

prevented.

The

other essential element is the spinning disc which is as simple as

effective in applying the coating liquids. The centralized spinning

disc is rotating at high speeds varying from 1500-6000 rpm.

The

other essential element is the spinning disc which is as simple as

effective in applying the coating liquids. The centralized spinning

disc is rotating at high speeds varying from 1500-6000 rpm.

At these

speeds coating liquid will be broken down into a mist of droplets in

a large spraying zone which enables a fast and homogeneous wetting

of the individual particles in the rotating mass.

From here it is easy to perceive that with such a

fast and even wetting of the particle surface, the absorption of

powder material and subsequent building of a pellet progresses

equally effective.

While this may explain the potential success of

the rotary pelleting as such, there is a great deal of parameters

and variables involved which determine the overall effectiveness of

the process and the attractiveness for commercial application in

seed encrusting and pelleting.