|

The ideal drill row spacing for maximum yield - The debate starts here

Grieskirchen, Austria

April 11, 2014

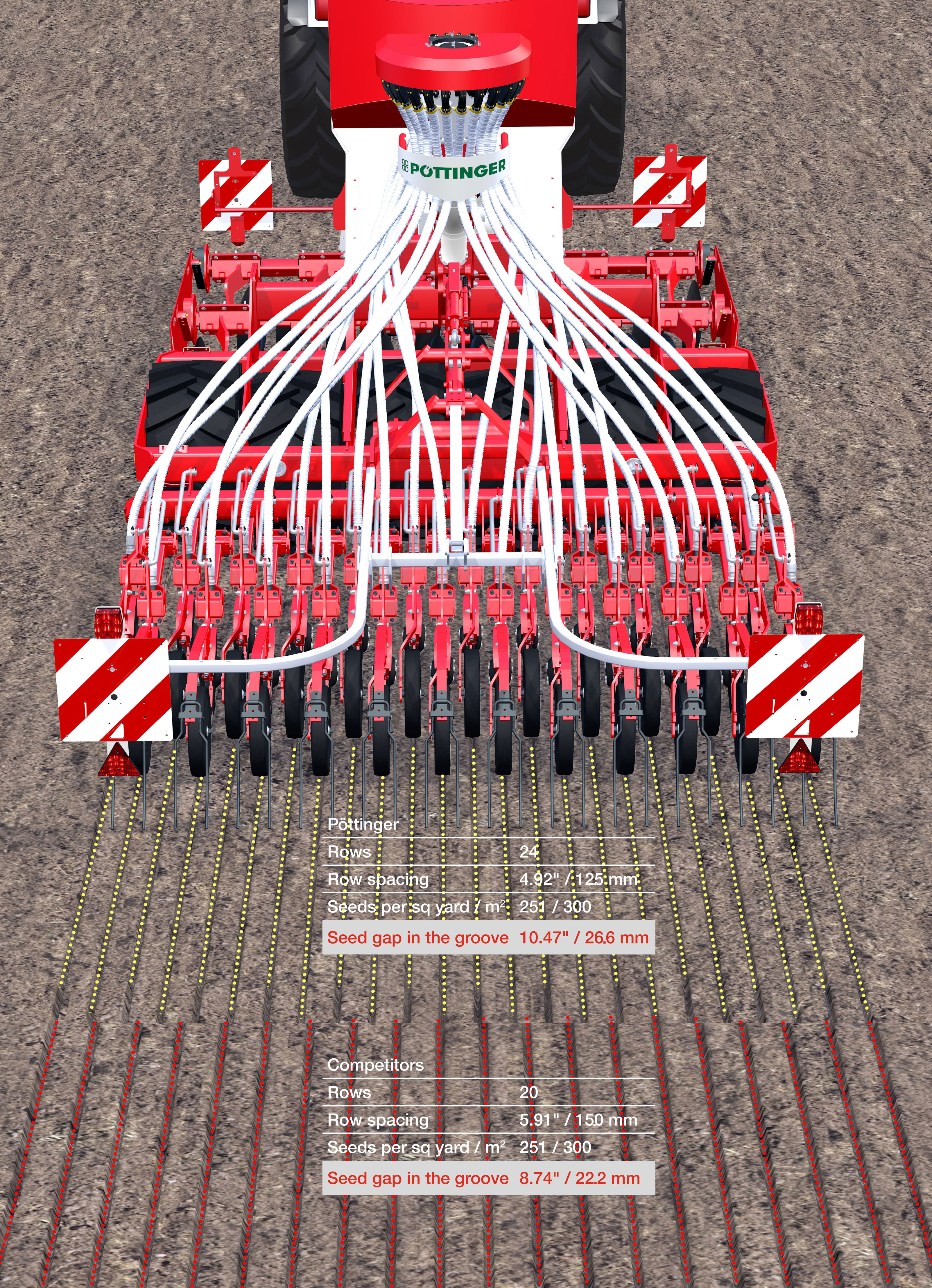

Terrasem Row spacing - Click to enlarge

Some people swear by a row spacing of 12.5 cm, others insist on 15 or even 16.7 cm to produce maximum yield. Which is best? What is the ideal drill row spacing? Find out which factors are critical in making this decision.

Recently, many technical innovations have been developed - some of them already available on the market - which are designed to improve the seed gap in the groove. The success of these systems has been limited, however.

There are several facts worth knowing that explain why: these so-called innovations are aimed primarily at machines with a large row spacing (15 cm or 16.7 cm). The seeds need to be placed closer together in the groove in order for the same quantity of seed per square metre to be sown with a wider row spacing. Hence the new methods of improving distribution in the seed groove (longitudinal gap) to prevent loss of yield. Implementing these new methods and technical innovations is supposed to increase yield by up to (a highly questionable) 8 percent as a result of better plant distribution density. That seems like a lot at first glance. The fact is, however, that machines with a smaller row spacing deliver better plant distribution density to start with. The smaller row spacing means 20 percent more rows on a drill with a working width of 3 m compared to a drill with a row spacing of 15 cm. That translates into 20 percent better seed density in the groove (25 percent better than a row spacing of 16.7 cm) and higher yield as a result. This is achieved without the extra development of technical solutions to optimise longitudinal seed gap in the groove.

So why, you might very well ask, are we even considering larger row spacing if narrower spacing is more efficient anyway? The answer is easy: different designs of coulter system and inter coulter rail spacing (the space between each gang of coulters) often force the manufacturer into producing larger row spacings, especially on mulch drills.

However, practical experience during planting shows that it is necessary to make modifications if drills with a larger row spacing are going to match the performance of narrower spaced machines. If we take a planting density of 300 seeds per square metre, for example, the theoretical longitudinal seed gap in the groove for a row spacing of 16.6 cm is 2 cm, on 15 cm drills it is 2.2 cm and on 12.5 cm machines it is 2.7 cm. Consequently, the wider the row spacing the more accurately the seed has to be placed in the groove. Otherwise, considerable losses of up to 1,000 kg yield may result - an enormous amount.

Additional advantages with 12.5 cm row spacing:

- Up to 10 percent saving on seed

- Faster ground coverage resulting in fewer weeds

- Shade provided sooner for improved micro-climate

- Protection against erosion

A slightly higher purchase price for a seed drill with a row spacing of 12.5 cm - and therefore more coulter elements and seed grooves - is more than compensated for by higher yield potential. An advantage that remains for the entire service life of the seed drill.

Pöttinger has investigated these factors in detail and offers the ideal solution with our latest TERRASEM technology.

More solutions from: Poettinger Maschinenfabrik Ges.m.b.H

Website: http://www.poettinger.at Published: April 11, 2014 |