Queensland,

Australia

March 29, 2006

Dr

Stuart Gordon (CSIRO Textile and Fibre Technology/ Cotton CRC)

explains new technology being developed to measure fibre

fineness and maturity the parameters desired by spinners. CSIRO

Plant Breeder Greg Constable talks about the factors that

influence fineness and maturity and how they are being improved

through plant

breeding. Dr

Stuart Gordon (CSIRO Textile and Fibre Technology/ Cotton CRC)

explains new technology being developed to measure fibre

fineness and maturity the parameters desired by spinners. CSIRO

Plant Breeder Greg Constable talks about the factors that

influence fineness and maturity and how they are being improved

through plant

breeding.

Stuart you have

been doing some work on fineness and maturity. Can you tell me

how those parameters are measured now and whatís wrong with

that?

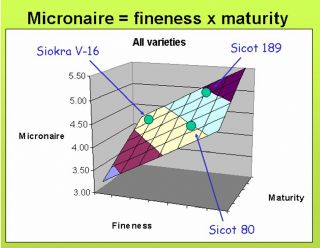

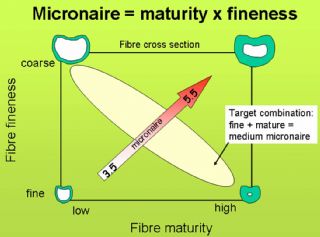

We use micronaire to get an

idea of fibre fineness but micronaire is a product of both

maturity and fineness because micronaire actually measures

specific surface area so it measures the airflow or measures out

the pressure difference between, the pressure difference over a

plug of fibres of a specific weight and those fibres can be

course and immature or they can be find and mature. So which is

it?

You are

developing systems that measure those two things independently,

starting with fineness, what is it and how are you proposing to

measure it?

Cotton fibre fineness is

defined in terms of mass per unit a length or gravimetric

fineness we call it or linear density and so we describe it in

terms of milligrams per kilometre and the term we use is militex

or desitex which is tens of grams per kilometre or desigrams per

kilometre but millitex is milligrams per kilometre and thatís

how we define fibre fineness. So for upland cottons we are

looking at millitex values between say 150 and 200 millitex

normally for Australian cotton. With 150 millitex being

preferred if you are looking to spin fine count yarns.

And

maturity. Whatís it and how do you measure it? And

maturity. Whatís it and how do you measure it?

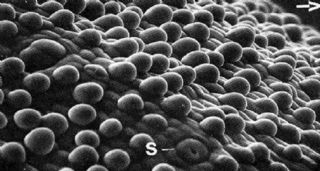

Maturity is a little bit more

difficult to measure. Its usually measured, currently its

measured relative to airflow or some other fibre parameter but

if we are to divide it in sort of first principles itís the

degree of thickening in the fibre wall. So cotton fibre is a

single cell and the thickness of that cell wall will define its

maturity and the way we measure in the first principles is we

actually section the cotton fibre and measure the cross

sectional area and express that as a ratio to the area of the

circle the same parameter as that cross section. So thatís the

definition of fibre maturity.

So sometime in

the future growers will be able to have through standard

classing houses have access to fineness and maturity rather than

just a single micronaire value?

Ideally, I think the spinning

industry for a number of years has been looking for that

segregation and if you look back in the literature and industry

forums over the last ten to twenty years there has been that

call for that differentiation of micronaire into its two

components and we hope at CSIRO that we have two new instruments

that will enable at least the Australian cotton industry to

start doing that and particularly at the breeding stage where we

are looking to have definition of new varieties based on the new

varieties that are fine and mature and I understand that the

environment plays a big hand in the cell wall development so its

environment still has a big factor there but if we can have

varieties that lean toward the finer end and that we are able to

grow to maturity then we will have a premium fibre.

From

a spinners prospective, the person thatís using the product.

Whatís going to be their preferences in terms of fineness and

maturity? From

a spinners prospective, the person thatís using the product.

Whatís going to be their preferences in terms of fineness and

maturity?

They are going to want a fibre

really around the sort of well, around the 150 to 160 millitex

mark and with a maturity ratio of about .8 or an average

maturity ratio .8. Now, I am using maturity ratio there which is

another scale again but I guess there also needs to be some

education about what scale of maturity we use so in saying that

we are just talking about a fibre. If a use a maturity ratio we

are talking about a fibre that has maturity ratio or 1 and if I

talk about the degree of thickening, which I defined before,

then we are talking about a value of about .8 or 7.8.

But in short they want a

fibre thatís fine but mature?

In short, they just want a

fibre thatís fine and mature and long and strong.

CSIRO

Plant Breeder Greg Constable CSIRO

Plant Breeder Greg Constable

Greg, we have just heard from

Stuart Gordon talking about how they have got instruments to

measure fineness and maturity and he has mentioned that the

spinners are really interested in a fine but mature fibre. Can

you just tell me starting with fineness, what are the main

determinants of fibre fineness?

There are different varieties

that are finer than others Dave and the very extreme is Pima. So

the Pima has this very fine fibre and within out upland

varieties there is a range there from varieties that are nice

and fine to varieties that are relatively course. Siokra V-16

was an example of a nice fine fibre.

So in terms of

say agronomic or climatic conditions what could influence

fineness?

Fineness will be initially

influenced by the conditions in that first 20 days of fibre

development because it can actually expand in diameter at that

time. But mainly the fineness will also be affected by

conditions during boll filling. So good warm sunny conditions

will increase the diameter of the fibre slightly and obviously

they will more thick.

Moving

on to maturity, what can influence maturity? Moving

on to maturity, what can influence maturity?

That is mainly from the

conditions during bolls, boll filing and fibre thickening. That

last 40 days of boll filing again sunny, warm conditions, good

water and nutrition will give a more mature fibre and if itís a

courser fibre it will end up with a higher mic.

Is there

varietal differences between maturity?

Absolutely, there is probably a

little bit more variation in our upland varieties for maturity

than there is for fineness. So some varieties have more mature

fibres than others.

Is that because

they fill those fibres for a longer period of time or do they

fill more per day?

Probably both and in the case

of most of the varieties we have got I imagine it is both but

the narrower sort of germplasm that we have these days is

probably more to do with per day rather than longer boll

periods.

How are you

using this fineness and maturity information in the breeding

program?

We have instruments here. We

have the older fineness maturity testers that are measured both

fineness and maturity and we use that in parallel with our HVI

line for measuring the fibre properties of breeding lines and we

are putting heavy selection pressure on for fine mature fibres.

The complexity is a) the fineness maturity testing is slower but

the most frustrating aspect is that fine fibres are correlated

with lower yield so we are always sort of struggling to make

advances with one while not changing another one.

Why do you

think there is that negative correlation between fineness and

yield?

Itís a good question and I

think its to do with the fact that there are a limited number of

fibres on the seed and if those fibres are finer or other words

smaller diameter there is not enough sync for actually filing

fibres and for setting cellulose which is our lint yield.

Further Information:

Robert Eveleigh, John

Marshall, Craig

McDonald, David

Kelly or

James

Quinn |