| Seed Coating Polymers and

Colorants

The UNICOAT™ and AQUACOAT™

proprietary polymer systems have been used to coat multiple millions

of pounds of seed, both as filmcoating and seed pelleting

applications.

UNICOAT™ polymers are made in high concentration form and are sold

as a 3:1 mixture formulation, meaning that one gallon of polymer is

mixed with 3 gallons of water to make 4 gallons of usable solution.

This allows us to ship the customer more workable gallons of

solution per truck load, making your cost per gallon, including

freight lower. UNICOAT polymers are available in many color

offerings as well as our newly trademarked “NUDE™” color, giving the

coating material product a natural seed appearance.

UC Systems also has the capability of custom blending colorants for

specialized customer requirements. Custom blending can be done on

bulk order amounts of 250 gallons or more.

|

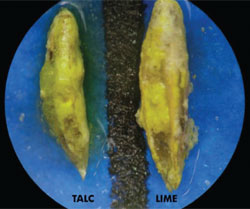

Figure 1

UNICOAT (left); Competitor (right)

The slide in Figure 1 compares

coatings of UNICOAT (left) and competitors coating (right).

UNICOAT provides a smooth, even, coat significantly reducing

“dusting off”. The competitors loss (dust-off) appears to be

nearly 30% of the coating. |

| |

|

|

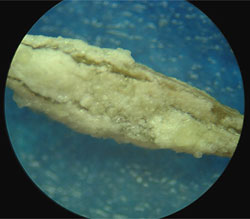

Figure 2

UNICOAT (left); Lime/polymer (right)

The slide in Figure 2 compares

UNICOAT with lime/polymer coating after wetting.

UNICOAT has significant coat coverage, and will stay on the

seed where it is needed, and not in the bag as waste. |

In answer to today’s water conscious environment, UC Systems has

developed AQUACOAT™. This seed coating polymer system has a highly

absorptive material incorporated within the polymer matrix. This

material is capable of holding 400-600 times its weight in water.

The absorbent material in AQUACOAT is capable of rehydrating many

times allowing the seed to make the most use of each water

application event. Unlike the competition, AQUACOAT’s absorptive

materials are incorporated within every coated seed during the

coating process. The competitor’s materials are added during the

coating process as a powder, where distribution is poor at best,

giving normally no more than 60% seed coverage. Much of that 60%

will fall off after application and during planting and not be

available to the seedling during germination. With AQUACOAT you can

be sure that what you applied is fully part of each and every coated

seed, EVERY TIME!

|

Figure 3

AQUACOATThe Figure 3

slide of AQUACOAT is taken 18 hours after the seed wetting

process.

The super-absorbency of this polymer allows the seedling to

survive for much longer periods between water application

events. |

AQUACOAT as shown in Figure 3 is a

unique polymer that is completely nontoxic and odorless. As water

comes into contact with AQUACOAT, the water-insoluble matrix

expands, encapsulating the seed within a moisture rich environment. |