Improver,

X-ray and Purifier

Introduction

Seed companies aim to market seed more than 99,9% pure

and with the best possible germination characteristics. During harvest

however, it is nearly impossible to obtain seed without undesired

intermixes of other crop- or weed seeds, sticks, chaff and other inert

material. These intermixes can seriously influence growth and yield of the

crop during the next growing season. Therefore seed cleaning and upgrading

are important phases in seed handling  processes after harvest.

Furthermore, clean and pure seed lots are of great importance to Incotec

especially for applying our coating and enhancement technology.

processes after harvest.

Furthermore, clean and pure seed lots are of great importance to Incotec

especially for applying our coating and enhancement technology.

Incotec

is specialised in improving seed quality to the highest possible

standards, and has a wide range of experience in polishing, upgrading and

mechanical scarification. These techniques are aimed at improving seed

germination characteristics and overall quality of flower, vegetable and

tobacco seeds.

Upgrading is performed through a range of technologies,

ranging from mechanical cleaning and upgrading, liquid density separation

and in the near future X-ray. Upgrading is marketed as a separate product

(e.g. Improver) or can be applied in combination with enhancement

techniques (e.g. Priming) and/or coating. Incotec offers you the following

upgrading products: Improver, X-ray

(in the near future) and

Purifier.

Figure 1. Liquid density separation

Improver

Conventional upgrading

With most conventional upgrading techniques, the seed

quality is derived from external characteristics like size and color. Seed

lots are cleaned to remove inert matter and weed or foreign seeds.

Differences between seeds in shape, width, length, color, weight, etc,

make it possible to separate a seed lot in two or more fractions.

Techniques that are based on density have a more direct

relation with the interior of the seed. The most advanced of these

techniques is the fluid density separation.

Fluid density upgrading

A very precise separation in fractions can

be obtained in solutions with different densities. This method may be

effective even after other upgrading methods have failed. A trial

upgrading always precedes a commercial production, as it is not possible

to predict the upgrading effect.

The graph shows the effect on germination

capacity (%) of three different tomato seed lots, by removing consecutive

fractions through fluid density upgrading. Although quality of lot A was

improved from 73 to 84% good seedlings, the maximum germination capacity

was reached after removing 30% of the weight. Lot B initially had 8 % less

good seedlings than lot C. By removing 20% weight, germination capacity of

both lots increased to 92%. However, efficiency of upgrading for lot B was

much higher than for lot C.

X-ray

Looking at the inside

X-ray radiography has been used since the

fifties for determining several seed quality aspects. Looking at the seed

interior, it can be assessed whether all the essential seed components are

adequately present, and if seed processing, pests or diseases, damage

seeds. Upgrading, based upon X-ray images, therefore appears to be a very

promising method, with little waste compared to conventional upgrading

techniques.

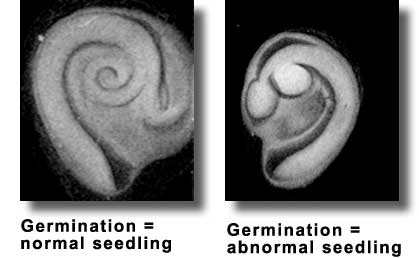

Research

Indeed, several investigations have shown

that by using X-ray radiography and manual selection, germination

characteristics can be improved. Research performed at Incotec indicated

that tomato seed lots could be upgraded to give a high level of usable

seedlings, in a much more efficient way than with conventional techniques.

Figure 2. X-ray images of normal and

abnormal seeds which result in normal and abnormal seedlings after

germination.

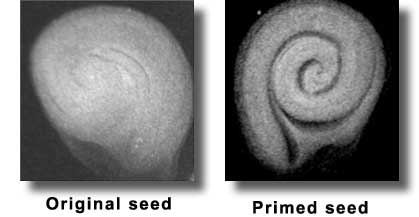

Need for priming

Before using X-ray, the seed has to be

primed. By priming, the seeds within a lot are advanced to the same level

of maturity, and would show the same level of detail when X-rayed. In

unprimed seed lots, many seeds do not show enough detail.

Figure 3. X-ray images of unprimed and

primed tomato seed.

Seed sorting system

So far, all the work has been done using

X-ray negatives and manual sorting. The good results incited Incotec to

develop a fully automated seed sorting system that uses X-ray technology.

In the system digitized images are analyzed by a computer system that

controls the sorting machine.

In close cooperation with three prominent

companies Incotec has, after several years of developmental studies,

almost reached the stage in which we can actually start the construction

of the first prototype.

Figure 4. Automated Seed Sorting System

With this prototype we would be pleased to

service you by offering trial X-ray separations in near future. Please

contact our Account managers for the latest news on the X-ray seed sorting

system.

Purifier

Plant breeders produce new variety and hybrid crops

every day. By using advanced techniques such as "male sterility"

or "Cytoplasmatic Male Sterility", pure hybrid fruits,

seeds and plants can be produced. Often, however, this is difficult to

accomplish. Seed companies have the task of removing the parent lines,

harvesting separately or removing the inbred seeds from the hybrid seed

lot after harvest.

Plant breeders produce new variety and hybrid crops

every day. By using advanced techniques such as "male sterility"

or "Cytoplasmatic Male Sterility", pure hybrid fruits,

seeds and plants can be produced. Often, however, this is difficult to

accomplish. Seed companies have the task of removing the parent lines,

harvesting separately or removing the inbred seeds from the hybrid seed

lot after harvest.

Besides years of experience in inbred removal from

hybrid seed lines, Incotec also has a range of technologies available that

can be used especially when the genotypic difference is not clearly

expressed as a morphological characteristic. With unique

technologies Incotec is often able to upgrade a seed lot with a hybridity

as low as 80%.

After

a trial upgrading, samples of different fractions are returned to the seed

company to determine the hybridity. On request however, Incotec can also

take care of the hybridity tests (protein electrophoresis). With the

determined hybridity results, confidence intervals are calculated to

determine the significance of the upgrading. The customer decides which

fraction(s) is significantly and sufficiently upgraded, and can be

produced commercially. Our upgrading specialists are always available to give expert

advice about this complex product. Please contact your local sales representative.