Scott, Mississippi

June 18, 2004More

efficient production planning and better inventory control among

the benefits

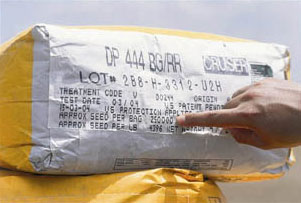

The new seed-count packaging introduced by

Delta and Pine Land Company

(D&PL) this year has simplified seed-ordering calculations and

put more efficiencies into inventory and input-cost management,

say seed distributors and dealers, as well as cotton producers.

D&PL sold Upland cotton varieties for the first time this year

in bags that contained a minimum of 250,000 seeds and Boll

Boxes(tm) that contained a minimum of 8 million seeds. Across

much of the U.S. Cotton Belt, feedback on the new seed-count

packaging has been positive. The packaging switch was a logical

next move, according to Ben Bailey, general manager of Jimmy

Sanders, Inc. based in Cleveland, Miss. D&PL sold Upland cotton varieties for the first time this year

in bags that contained a minimum of 250,000 seeds and Boll

Boxes(tm) that contained a minimum of 8 million seeds. Across

much of the U.S. Cotton Belt, feedback on the new seed-count

packaging has been positive. The packaging switch was a logical

next move, according to Ben Bailey, general manager of Jimmy

Sanders, Inc. based in Cleveland, Miss.

"So many of our producers have gotten away from planting pounds

of seed per acre, and have begun to plant seeds per row-foot

with new, precision-type planters," he says. "Seed-count

packaging fits right into that practice."

Knowing that there are 250,000 seeds per bag makes it easier to

figure how many bags are needed to plant a desired number of

acres, helping producers manage input costs more efficiently.

"Initially, there was some confusion because everyone was used

to dealing in 50-pound bags," says Terry Boone, a cotton

producer and independent seed dealer in Jackson, N.C.

Farmers knew that it took them so many 50-pound bags to cover a

certain amount of acres. Many producers doing business with

Boone's Farm Supply have already switched from planting pounds

of seed per acre to planting seeds per foot of row. Dealing in

seed-count bags allowed them to become more accurate in figuring

out the number of units needed to plant the acres they had to

plant, says Boone.

"I had one producer come in and tell me that he loved seed-count

packaging," he says. "He was right on the money in figuring out

the number of bags he needed and he had no bags to return. We

also had a few farmers get confused and wind up having more

units to return. It's going to be a slight adjustment, but in

the long run, it's going to be good for the industry."

The new D&PL seed-count packaging has eliminated questions

raised by producers in Georgia about bags of the same variety

containing different number of seeds, resulting in differences

in cost of seed per acre. Joe Dixon, owner of Dixon Seed and

Chemical in Alapaha, Ga., says with seed-count packaging this

year, he has had no complaints.

"Once everyone got used to the fact that every bag contained

250,000 seeds, they felt like they were getting a fair deal -

that everyone was paying the same amount for seed," says Dixon.

The new D&PL seed-count bags helped Brad Hill of Tulia, Texas

understand exactly what he was getting for his money. Hill, who

farms 1,200 acres of cotton, says with the old 50-pound bags,

he'd check each bag for the seed-count per pound and use his

calculator to figure the cost of seed and the number of bags

needed to plant his acres. With seed-count bags, all that has

become easier.

"I know exactly what I'm getting for my money, now," says Hill.

"I know the same amount of money will buy me 250,000 seeds of

one variety."

Before D&PL introduced seed-count packaging, bags contained a

seed-count per pound, which could vary from bag to bag. Hill

dumps one bag of seed in each of the hopper boxes on his

planter. If each bag contains a different seed count, he gets a

different seeding rate in each row.

"There was no way of getting around that for me with my planter

until seed-count packaging came along," he says. "Planting

different seeding rates in each row can be costly. Now, I know

that when a hopper box is empty, I have planted 250,000 seeds."

The new D&PL seed-count bags make ordering his seed easier, as

well.

"There is no longer any guesswork in figuring out how many bags

I need to plant a certain amount of acres," he says. "I don't

have to look at each bag's seed count and use my calculator to

figure all that up. With seed-count packaging, I know that I

need a certain amount of bags to plant a certain number of acres

based on my desired seeding rate. I much prefer seed-count

packaging over the old way."

From a seed distributor standpoint, says Buddy Vandevender, who

manages the Hollandale, Miss.-location of Jimmy Sanders, Inc.,

seed-count packaging means better inventory control.

"Ordering the right amount of inventory to cover an area is

easier with the new packaging," he says.

With the old 50-pound bags that contained a range of seeds per

pound, a general way to factor the number of bags needed to

plant a desired number of acres was to multiply 10 pounds per

acre. It was not an exact science, sometimes leaving a producer

or distributor with more seed than they needed.

"After the first year of handling the new D&PL seed-count

packaging, we have fewer bags left over in inventory at the end

of the planting season," says Vandevender. "We've been able to

manage our inventory better."

To generate seed-count packaging, D&PL developed and implemented

an entirely new process of handling and packaging seed that

offers customers better flexibility on orders and timely

delivery of finished goods. Specially-designed, patented

high-tech equipment was built for the D&PL packaging plants

allowing the company to package in seed-count units.

Due to the various sizes and densities of seed varieties, D&PL

seed-count bags can range in weight, going below or above the

traditional 50-pound weight limit the industry had become so

accustomed to.

"We had no problems reported with the range of weights and sizes

of the bags," says Freddie Miller, southern seeds manager for

Land O' Lakes Seed in Memphis, Tenn. "This biggest thing we

found was the learning curve of figuring the number of units

needed to cover X-amount of acres. Everyone was used to the old

way, but once they understood the new equation using seed-count

units, I think it became easier."

In the past, lots of seed had different seed counts, making it

more difficult to figure out how many bags were needed. Now,

says Miller, it's easier because every bag contains 250,000

seeds and every Boll Box contains 8 million seeds.

"This is where we should be" he says. "This is best for the

industry. Seed-count packaging has certainly put more efficiency

in inventory management for the distributors and seed dealers."

The new D&PL seed-count packaging has also shed more light on

the cost of seed and everything associated with it, including

technology fees and chemical treatments. Seed-count pricing

makes price breakdown on seeds more apparent and easier to

figure out, says Boone. This allows the producer to better

manage his input costs and make better business decisions.

"The producer can better compare cost of varieties now, and he

knows what it is costing him right down to the single seed," he

says. "Allowing the farmer to better manage his input costs is

the biggest advantage to seed-count packaging. Seed is a big

front-end investment for the farmer, so knowing the cost

breakdown better enables him to make more educated decisions."

Going forward, seed-count packaging is preferred over the old

50-pound bags of seeds that contained a range of seed counts.

"I wish the whole industry was doing this," Boone says. "There

are many advantages to this for everyone - seed distributors and

dealers, as well as producers."

Delta and Pine Land Company is a commercial breeder, producer

and marketer of cotton planting seed, as well as soybean seed in

the Cotton Belt. For almost 90 years, the Company has used its

extensive cotton plant breeding programs drawing from a diverse

germplasm base to develop improved varieties. Delta and Pine

Land (NYSE: DLP), headquartered in Scott, Mississippi, has

offices in eight states and facilities in several foreign

countries.

Ball Box is a trademark of

Delta and Pine Land Company. |